Description

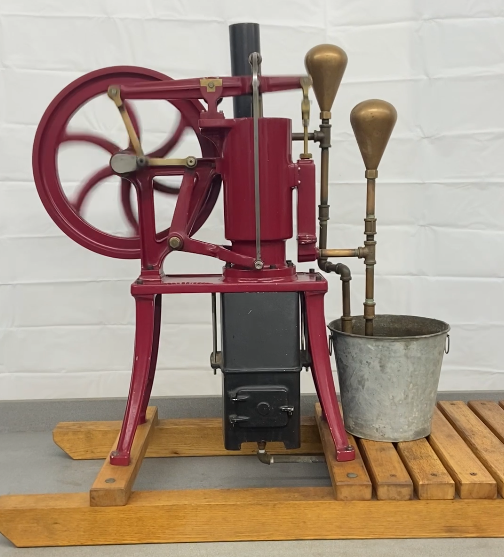

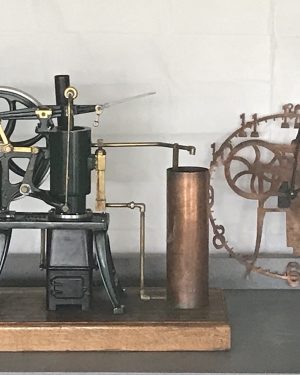

The Ericcson style engine is a “beta” engine, which contains both the power piston and displacer within one cylinder. The cylinder has a hot end within the firebox, and a cold end, surrounded by a water jacket. As the air is heated within the cylinder, the air expands, driving the piston upward. The displacer next moves downward, pushing the air from the hot side into the cool side of the cylinder. The air then contracts, pulling the piston downward. The displacer then moves the air from the cool side to the hot side, the cycle begins again.

The Rider-Ericcson hot air engine, circa 1880 was used to pump water to the upper floors of the house. An engine was placed in the cellar and a tank in the upper part of the house. The water was pumped from the mains to this tank. This engine introduced the “Luxury of water” to our ancestors. These engines were also used at the well sites…spring, well, cistern or brook.

The advantages of the Rider-Ericcson was that it was absolutely safe; no steam, practically noiseless; could be used at any time when needed; no licensed or experienced engineer required; simple and durable; could be used in many places where any other device or machine would be objectionable or impossible.

3 inches bore

3 inches diameter cylinder bore

25 inches high (to top of flywheel)

20 3/8 inches long

9 ¼ inches deep

13 inches diameter flywheel

Prints

12 Aluminum castings

2 legs

Firebox and door

Yoke

Flywheel

Beam

1 iron casting (piston)

2 pieces of steel tubing

Stack elbow and pipe

base

cylinder

cylinder knee

beam bracket

pump